What you need to know about GHS label requirements in your workplace

GHS labels are not just for chemical manufacturers. In reality, there are chemicals in your workplace, no matter where you work. This is true whether you’re in an office, at a job site, manufacturing products, or managing a warehouse. It’s important to realize that some of those chemicals are potentially hazardous. You should understand GHS label requirements because doing so can increase safety and compliance in your workplace.

For example, even in our Avery offices, we use GHS labels for hazardous chemicals like cleaning solutions stored in secondary containers. As a matter of fact, we’ve previously written about secondary container labeling tips to help you ace OSHA inspection. We also use them for chemicals stored in our Research and Development lab. The R&D team regularly tests Avery products and printing methods for chemical resistance.

In this article, we’re covering everything you need to know about GHS label requirements. Additionally, we’ll show you not only how we use our GHS products to increase safety and compliance, but how you can create your own too.

More chemical safety articles you might like:

- Safety & Compliance: Step-by-Step Guide to Reviewing & Updating SDS

- 5 Easy Tips to Avoid the Most Common OSHA Violations

- How to Create GHS Labels Using the Avery GHS Wizard®

What are GHS labels?

Essentially, GHS labels are a very specific type of chemical safety sticker. They feature standardized symbols, words, and information to make it easier for workers around the world to understand the labels. Of course, the primary function of the GHS label requirements is to help employers communicate hazards better. However, in many cases, U.S. law requires them on hazardous chemical containers as well.

The Globally Harmonized System (GHS)

To further explain, GHS stands for Globally Harmonized System. Both are common, shorter ways people refer to the United Nations document entitled The Globally Harmonized System of Classification and Labeling of Chemicals. You may also know this document as “The Purple Book.” The creators of The Purple Book had two main goals. Firstly, to provide an internationally standardized way to classify chemicals by type. Secondly, to align (or harmonize) the way chemical safety inform

That being said, the UN document is not a law. However, it is a set of guidelines that many consider best practices for chemical safety in the workplace. Yet many people mistakenly refer to the UN document, in and of itself, as a law because OSHA adopted it on March 26, 2016. When OSHA adopted the GHS guidelines, it was as a revision to the existing OSHA HazCom standard, which is the actual law that you must follow if you operate a business in the United States. Since the guidelines are now part of an OSHA standard, you must follow them if they apply to your business.

GHS labels versus dangerous goods labels

In summary, here is a table to explain the key differences between GHS and the requirements for dangerous goods:

| Type of Label | What | Where | Who |

| GHS | Hazardous chemicals | U.S. & overseas | OSHA |

| Dangerous Goods (TDG) | Hazardous chemicals Hazardous articles | Overseas | IMO |

Businesses use both GHS and dangerous goods labels to signify hazardous substances. However, there are three key differences between them. While you must use GHS labels for hazardous chemicals, you would use dangerous goods labels for hazardous chemicals and/or “articles.” Lithium batteries, for example, are a potentially hazardous article that would require a dangerous goods label.

Secondly, you will find danger goods and GHS label requirements listed in two different documents. GHS requirements are listed in OSHA HazCom standard 1910.1200, while dangerous goods requirements are listed in the International Maritime Dangerous Goods (IMDG) Code. Lastly, different agencies enforce compliance with the two sets of guidelines. In brief, OSHA enforces GHS compliance for chemicals manufactured, used, or received in the U.S. as well as those shipped from the U.S. In contrast, the IMDG code applies to hazardous materials shipped overseas, and it’s enforced by the International Maritime Organization (IMO).

Are GHS labels the same as transport labels?

The short answer is no. Regular transport labels are used for logistics and tracking, whereas GHS labels are used for safety. However, dangerous goods labels are also called Transport Dangerous Goods (TDG) labels. As mentioned above, TDG and GHS labels are both used for safety, but they have several key differences.

Another difference is simply location. You must place TDG labels on the outside of pallets and containers. In contrast, GHS labels must be affixed directly to the hazardous chemical container as well as the inner and outer boxes.

Why you should follow GHS guidelines in your workplace

Safety concerns

Protecting human life and health is, of course, always the top priority. One way employers can do that is to adequately identify workplace hazards. This helps prevent hazards and tells workers what to do in an emergency. That’s why the UN developed GHS guidelines. They wanted to make such information about hazardous chemicals more easily understood by workers, regardless of location and even language. The GHS pictograms in particular transcend language, allowing workers to identify chemical hazards with a single glance.

OSHA compliance

The safety of workers should be enough of a reason to embrace compliance. However, because the OSHA HazCom regulations are enforceable by law, you can also incur severe penalties for not following them. In fact, OSHA non-compliance penalty fines range from $16,131 per violation to $16,131 per day beyond the abatement date up to $161,323 for repeated or willful violations. HazCom violations, including failure to properly label chemicals, regularly place near the top of the yearly list of violations from OSHA. One way you can avoid this very common OSHA violation is to pay closer attention to GHS label requirements when labeling workplace chemicals.

What containers need a GHS labels?

GHS label requirements included in OSHA HazCom regulations primarily affect three types of businesses:

- Businesses that manufacture hazardous chemicals

- Businesses that import and/or distribute hazardous chemicals

- Any company that uses hazardous chemicals in processing or other workplace operations.

In general, OSHA regulates businesses that fall into one of the three categories above and requires them to follow GHS guidelines for chemical safety. However, there are several exceptions to this rule depending on what types of chemicals you use, where you use them, and how you use them.

Most common HazCom exemptions

Consumer chemicals used in the same way a consumer would use them

If your employees use a consumer chemical (i.e., a product anyone can buy), you may not need GHS labels. However, depending on how you use the chemicals, you will still need to understand GHS label requirements. Consider this scenario: You give your employees household bleach wipes to use for disinfecting their workstations and tools. In this scenario, they are using a consumer product the same way a consumer would use it. Even with increased use, for example, employees disinfecting more often during an outbreak (such as COVID-19 or the flu) are still using them the same way any consumer would. In these instances, the safety information on the consumer packaging is sufficient.

On the other hand, let’s say you provide a bottle of common household bleach for janitorial workers to use for disinfecting. This would require you to be GHS-compliant, including providing available Safety Data Sheets (SDS). Generally speaking, janitorial employees using bleach will use it more often (and/or for longer periods of time) than the average consumer.

Workplace containers using HMIS/NFPA labels

Once a chemical leaves your facility, it must have a GHS label. Period. However, chemical containers that workers only use within your facility are somewhat of a gray area when it comes to OSHA HazCom.

You can use NFPA/HMIS labels for workplace chemicals if the training you provide employees is equal to what they would receive if they had access to the full GHS-compliant label. This can be tricky because if something goes wrong and your company chose to use NFPA/HMIS instead of GHS labels, there is a possibility you could be liable. We will explore this more in the sections below.

Secondary container exemptions

Only some secondary containers are exempt from any kind of chemical safety labeling, and only when specific conditions are met. Firstly, the employee who transferred the chemicals from the primary container must be the one who uses them. Secondly, the employee must use the chemicals in the secondary container immediately.

Consider the disinfection scenario above. A janitorial employee might transfer bleach from its primary container into a secondary container for diluting, use the solution, and then dispose of it afterward. In this case, you do not need to follow GHS label requirements because the same employee used the solution during the same shift.

Additional GHS exemptions

Chemicals regulated by another agency

Aside from OSHA, the Environmental Protection Agency (EPA) is the most prominent agency that regulates chemicals in the U.S. Particularly ones determined to cause unreasonable risk to public health or the environment. In particular, the Toxic Substances Control Act (TSCA) covers most of the chemicals regulated by the EPA. Six chemicals that are specified in the basics of the statute are: polychlorinated biphenyls (PCBs), asbestos, radon, lead, mercury, and formaldehyde. However, the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) provides for EPA regulation of pesticide safety among agricultural workers and other pesticide handlers as well.

Three other entities also regulate various chemical products. They are the Consumer Product Safety Commission (CPSC), the Food and Drug Administration (FDA), and the United States Department of Agriculture (USDA). The CPSC regulates labeling for consumer chemical products. The FDA regulates cosmetics and drugs for personal consumption. The USDA regulates food substances.

Chemicals regulated by a different OSHA standard

OSHA does, in fact, regulate hazardous chemicals used in laboratories. However, the rules for labs are not within the HazCom standard that incorporates GHS. Instead, you must label lab chemicals according to the Occupational Exposure to Hazardous Chemicals in Laboratories Standard (29 CFR 1910.1450).

Can you use HMIS & NFPA instead?

The official answer from OSHA regarding HMIS and NFPA is, “Yes, OSHA will continue to allow NFPA and/or HMIS rating systems on labels and SDSs as supplemental information. However, the rules for labeling and placement on the SDS still apply.”

The OSHA page above goes on to explain that the current regulations allow for the use of existing labeling systems like HMIS and NFPA (based on HCS 1994). However, they are only allowed as long as they are consistent with the current requirements of the HCS. Additionally, you can only use supplemental labels on chemicals onsite within the facility, and employees must understand the specific physical and health hazards.

When to choose GHS over HMIS & NFPA

From 1994 to 2012, there were two prevalent voluntary workplace labeling systems. One was the Hazardous Materials Identification System (HMIS), and the other was the National Fire Protection Association (NFPA). Indeed, HMIS and NFPA labels were the most widely used chemical labels for OSHA HazCom prior to the initial adoption of GHS guidelines in 2012.

The grace period for required businesses to fully convert to GHS ended in 2016. Yet the question of whether to continue to use the previous voluntary workplace labeling systems or move to GHS is still very common. Here are three good reasons to convert if you are still using HMIS or NFPA.

Reason No. 1: Shipments of new chemicals coming into the facility will have fully compliant GHS labels. If you use HMIS or NFPA labels for workplace secondary containers, then you must train employees to use both systems. Therefore, moving to GHS-compliant HazCom labels streamlines training into one system.

Reason No. 2: OSHA regulation 1910.1200(f)(6)(ii) outlines the information required on hazardous chemical labels. This information includes physical and health hazards. However, you will not find this information on HMIS or NFPA labels.

Employers that use an HMIS or NFPA label instead of a GHS label must prove that employees understand the hazards as well as they would with a GHS label.

Reason No. 3: The numbering systems for HMIS and NFPA are the opposite of GHS. One is the most serious hazard rating for GHS and the least serious for both HMIS and NFPA. While GHS labels do not display the hazard rating numbers, this still has the potential to cause confusion.

Visual GHS requirements

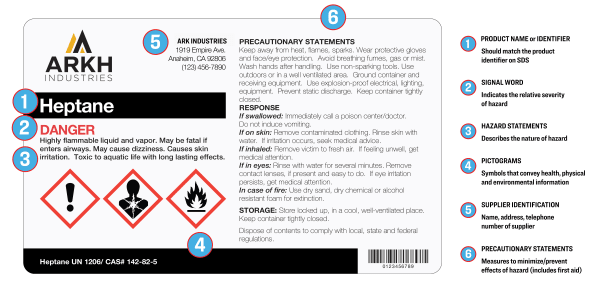

6 elements of a compliant GHS label

- Product Name/Identifier. This should match the product identifier on the Safety Data Sheet.

- Signal Word. Signal words ensure GHS chemical labels indicate the relative severity of the hazard.

- Hazard Statement. The nature of the hazard must be described on GHS chemical labels.

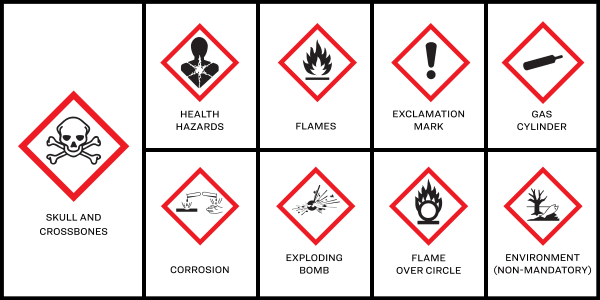

- Pictograms. Globally standardized symbols convey health, physical, and environmental information to transcend language barriers.

- Supplier Identification. GHS chemical labels must include the name, address, and telephone number of the supplier.

- Precautionary Statements. Any measures that could be employed to minimize and/or prevent the effects of the hazard must be communicated on GHS chemical labels. This includes first aid.

Does OSHA require pictograms?

For any container that requires GHS labels, yes! And they are incredibly specific. GHS pictograms are specific graphics that communicate the hazards associated with a hazardous chemical. The creators of the GHS system designed the pictograms to quickly and efficiently communicate chemical hazards without words. There are nine GHS pictograms in total, and OSHA regulates even the colors and shape.

Specifically, Appendix C.2.3.1 to 29 CFR 1910.1200 states that the shape must be “a square set at a point,” which simply means a diamond shape with four right angles. GHS pictograms must also include a black hazard symbol on a white background with a red border that’s wide enough to be clearly visible.

GHS label durability requirements

GHS labels for the average workplace versus those for chemicals shipped overseas have very different durability requirements. This is because: (1) the marine environment is extremely demanding, and information must remain intact for whoever receives the shipment; (2) if a hazardous chemical shipment is lost at sea, information must remain intact for clean-up crews.

Durability requirements for the average workplace

For the average workplace, you only need to consider a few things when it comes to GHS label durability. Firstly, you want to make sure the label stays in place, so a strong adhesive is a must. Secondly, you want the label to stay intact, so durable materials like film are better to use than paper. Lastly, it’s important that the print on the label remains legible. Water and chemical resistance will reduce smudged and smeared information that is not easy to read.

Specifically, OSHA guidelines for GHS state that “…the employer shall ensure that each container of hazardous chemicals in the workplace is labeled, tagged or marked…” with the appropriate information specified elsewhere in the standard.

Citations can be issued if the required safety information is no longer legible or intact. So it stands to reason that they should be durable enough to preserve the label information in heavy-duty environments.

GHS label durability requirements for shipping overseas

Conversely, GHS labels for chemicals shipped overseas have extremely specific durability requirements. Of course, there is a very good reason for such strict standards. GHS labels are meant to ensure that workers can accurately identify hazardous chemicals, even if there is an accident and the containers end up in the ocean. These very specific guidelines are spelled out in the British Standard BS5609, which we wrote about in depth here.

In summary, if you are shipping chemicals via ocean freight, the BS5609 rules apply to you because they are included in GHS guidelines. Additionally, the BS5609 rules were set by the International Maritime Organization (IMO) and are also required for International Maritime Dangerous Goods (IMDG) certification.

BS5609 certification summary

Basically, in order to achieve IMDG compliance, GHS chemical labels must meet the standards specified in BS5609 Sections 2 and 3. BS5609 Section 2 requires that the blank GHS chemical label and adhesive can withstand a three-month saltwater submersion test. It also includes artificial salt spray and sunlight weathering tests. Section 2-certified GHS chemical labels mean the label material itself (before any printing) is compliant with BS5609 Section 2 standards.

Furthermore, BS5609 Section 3 requires the fully printed label to meet or exceed certain standards for abrasion resistance and permanence of print. This includes testing printed GHS chemical labels with the same artificial salt spray and sunlight weathering, plus additional tape removal and abrasion resistance testing. Section 3 tests are conducted on specific GHS chemical labels printed by specific printers.

It’s important to note that BS5609 certification is always done by a certified third party, never by the label manufacturer. However, at Avery, our Research and Development team actually tests our GHS labels quite rigorously before sending them for BS5609 certification. We even have an entire article devoted to recommended printers for our GHS labels.

How we use our own GHS tools for safety and compliance

Like many companies, Avery does not manufacture, ship, or sell chemicals, but we still have them in the workplace. For one thing, Avery Facility Maintenance Technician Manny Padilla oversees the use of several mixtures for cleaning and disinfecting on a daily basis. Additionally, our R&D team uses chemicals to test the chemical resistance of Avery products. Of course, every employee also has access to bleach wipes, hand sanitizer, and screen cleaner for use as needed.

1) Identify containers that need GHS labels

The bleach wipes, hand sanitizer, and screen cleaner that we use around the office are consumer products that remain in their original packaging. Because we use them the same way any consumer would, there is no need to put GHS labels on them. The safety information on the consumer packaging is sufficient.

However, both Manny and the R&D team use chemicals in secondary containers, so they have to use chemical safety labels on them. As mentioned above, secondary container labeling can be a bit of a gray area, so our teams use GHS labels to be safe. While it could be compliant to use HMIS or NFPA labels, both teams agree that GHS labels are easier to understand and thus safer for Avery employees.

Examples of containers we label

To break it down even further, there are specific reasons why we use GHS labels on our secondary containers. Firstly, Manny transfers cleaning chemicals from their primary containers into secondary containers, where he mixes them with water to create the right solution. Most often, he stores the solutions in spray bottles for cleaning general surfaces. However, he uses other bottles for solutions that will be used in buckets for mopping. Because he is storing solutions for future use by himself and others, Manny uses GHS labels for these cleaning solutions.

Secondly, it’s not practical for the R&D team to lug around large containers while testing, so the chemicals are transferred to smaller containers for daily use. Moreover, even if it’s something commonplace like isopropyl alcohol, while testing, the R&D team uses the chemicals significantly more than the average person would. For these reasons, they use GHS labels on the secondary containers.

2) Create and print GHS labels onsite

Both Manny and the R&D team use printable Avery UltraDuty® GHS labels and the GHS Wizard® to create secondary labels onsite. We don’t have any special equipment in the office to do this. Whoever is making the labels just uses one of the office printers, a laptop, and the SDS that came with the chemicals.

Choosing a label

The process starts with choosing a label size that fits the container. Since the office printer our teams use is a laser printer, the labels they pick also need to be compatible with laser printers. In fact, previously, we’ve written in depth about why it’s important to choose the right label for your printer.

For spray bottles, Manny uses Avery 60503 3-1/2″ x 5″ UltraDuty labels for laser printers. For smaller, portable secondary containers, both teams prefer 2″ x 4″ 60505 laser-printable UltraDuty labels. However, if you have a pigment-based inkjet printer, you can find both sizes (and more) for pigment-based inkjet printers here.

Filling in GHS information

The next step is to log into an Avery account with a paid GHS Wizard subscription. Once you choose a template and enter the product name or identifier, the GHS Wizard pulls information from a database of over 30,000 chemicals. For example, the R&D team can simply open a GHS template for the label they’re using and type in “isopropyl alcohol.” The GHS Wizard will then fill in the template spaces for product name or identifier, signal word, hazard statement, pictograms, and precautionary statements. Then, the person making the label can check the information against the SDS and edit anything if needed.

The last step is printing the label on the office laser printer. The whole process takes about five minutes, and whoever is making the labels can print just one or dozens. Our teams prefer to print right then and there for convenience, but we also offer options for ordering custom-printed GHS labels through our WePrint service.

3) Train employees how to use and read GHS labels

OSHA 1910.1200(e)(1) requires employers to have a written hazard communication program. Part of the requirement is that you must describe how you will provide chemical safety labels, SDS, and employee training. Like many companies, Avery uses free OSHA training courses and other online resources to train employees on how to use and read GHS labels. This free tutorial video online is a great example of one of the resources our teams use to train employees on GHS labels.

4) Regularly review and update GHS labels

On the other hand, the only part of the OSHA HazCom standard that covers updating GHS labels is 1910.1200(f)(11). This subpart makes it clear that you must update GHS labels whenever new information is received from the manufacturer or supplier. Of course, the teams at Avery follow this rule; however, we also review and update GHS labels as part of our annual safety program review. Generally, it’s considered best practice to review safety programs once a year (which we wrote about here), and our teams agree. Choosing to review more often is an investment in compliance, as well as the safety of employees and their peace of mind.

Key takeaways for GHS label requirements

First and foremost, it’s important to know that wherever you work, it is likely that there are hazardous chemicals used. Yes, even in an office. For the most part, if you do not manufacture or ship chemicals, GHS labels are not required. However, you likely must use chemical safety labels of some sort in order to be compliant. In fact, there are two situations in which you must use chemical safety labels even if you are using regular consumer products. Firstly, when you store hazardous chemicals (like cleaning solutions) in secondary containers that are used by more than one employee or more often than during one shift. Secondly, when the employees using the chemicals are using them more frequently than the average consumer would.

This being the case, many workplaces choose to use GHS labels anyway in order to better protect their employees and avoid OSHA penalties. Generally, there are three reasons why safety professionals consider GHS labels to be the safer choice. For starters, they are simpler to understand regardless of language. Secondly, GHS labels contain physical and health hazards (HMIS and NFPA labels do not). And lastly, incoming chemicals will have GHS labels, so sticking with one methodology is less confusing for employees.

Summarizing the use of GHS labels at Avery

For all of these reasons, our facilities and R&D team use GHS labels for hazardous chemicals. Moreover, we use Avery UltraDuty GHS labels, not just because we make them but because they meet (and exceed) durability requirements for the chemicals we use in our office building. Of course, if we manufactured or shipped chemicals, UltraDuty GHS labels would also meet BS5609 durability standards. We also use the Avery GHS Wizard to create GHS labels for our facilities because it’s practically a no-brainer. Five minutes is about all it takes to create labels with the GHS Wizard, and we definitely value efficiency around here!