Arc Flash Safety: A Simple Guide to More Effective Labels

What should be on arc flash labels?

Arc flash labels typically contain key information for worker safety.

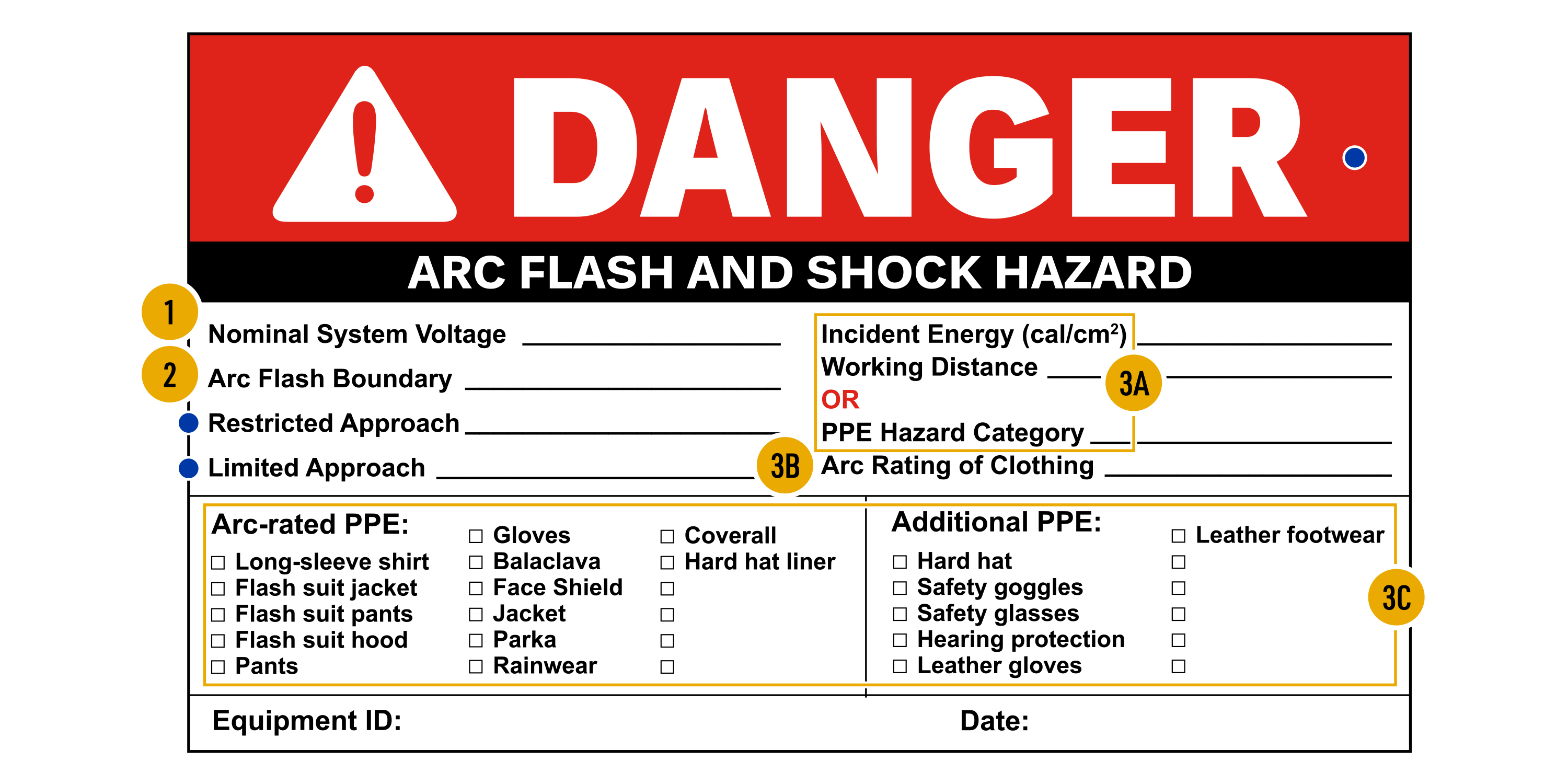

Required elements (NFPA 70E) include:

- Nominal system voltage

- Arc flash boundary

- Incident energy level or maximum approach distance

- Or, required Personal Protective Equipment (PPE) information

Additional elements (best practices) may include:

- Danger or warning headers

- Restricted approach boundary

- Limited approach boundary

Following this format ensures clear communication and helps workers understand electrical hazards. Additionally, we’re sharing tips for how to create compliant arc flash safety labels and answering important, frequently asked questions about them.

Watch a short video with tips for printing on Avery labels.

How to create compliant arc flash safety labels

The first step to creating compliant arc flash labels is to make sure you have all the key information handy. The next step is to choose the best label size and material for where you intend to apply the label. After that, you need to choose a design that aligns with OSHA and/or ANSI standards for safety communications in the workplace. Finally, customize your labels with the correct information, then print them.

Best sizes and materials for arc flash labels

For arc flash labels, the most important thing is to choose durable materials like our adhesive vinyl labels or our UlraDuty® GHS labels. UltraDuty film labels are waterproof PET labels for chemical containers. In fact, GHS labels are some of the toughest you can find because they have to be designed to withstand extreme temperatures, UV rays, water submersion, and other harsh elements. Vinyl labels have similarly high resistance to UV rays and water, but in general, are also thicker than most labels.

Regardless of the material you choose, remember to always choose labels for the type of printer you have. For instance, if you try to use laser-printable labels with an inkjet printer, the ink will not be stable and will simply never “dry” or set. If you try to use inkjet-printable labels with a laser printer, your labels may melt. In general, you will need a laser printer for heavy-duty materials like vinyl and waterproof GHS film.

Top sizes for arc flash labels

Avery GHS labels are available in convenient retail packs in various sizes that work well for arc flash safety labels. However, both GHS film and vinyl labels are available by the sheet in any size you need—including custom sizes, which you can choose for free. That being said, here are the label sizes that generally work best for arc flash safety:

- 3.5″x5″

- 5″x7″

- 7″x10″

How to find and customize Avery templates

Here is what you need to know to use Avery Design and Print Online (ADPO) to create custom arc flash safety labels for free:

- Go to our template finder page and enter your Avery product number.

- Select the layout of your labels (e.g., portrait or landscape).

- Choose the free template design you want to use.

- Enter custom text, pictograms, colors, etc. as needed.

- Preview, save the project and then download the PDF to print.

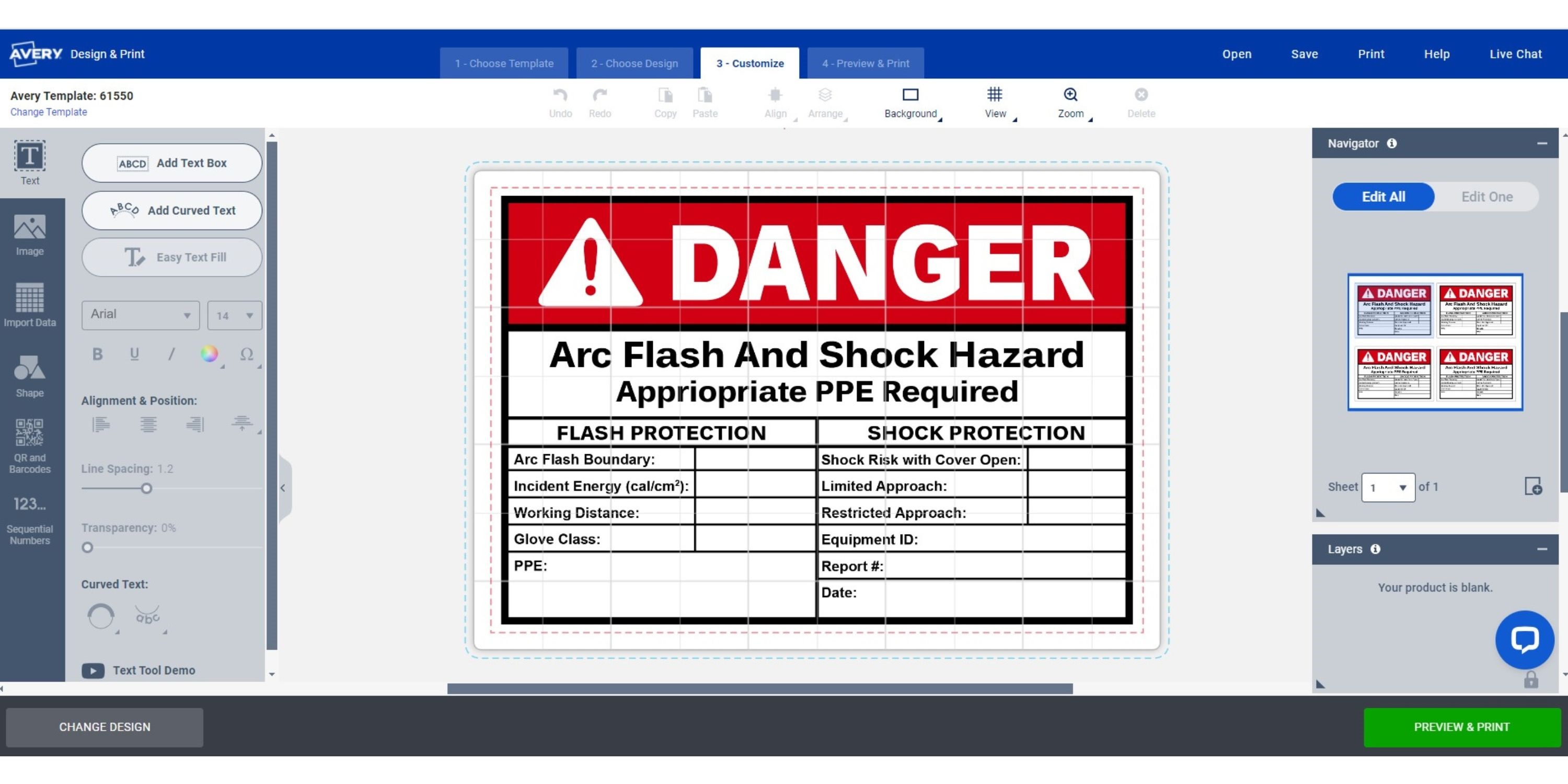

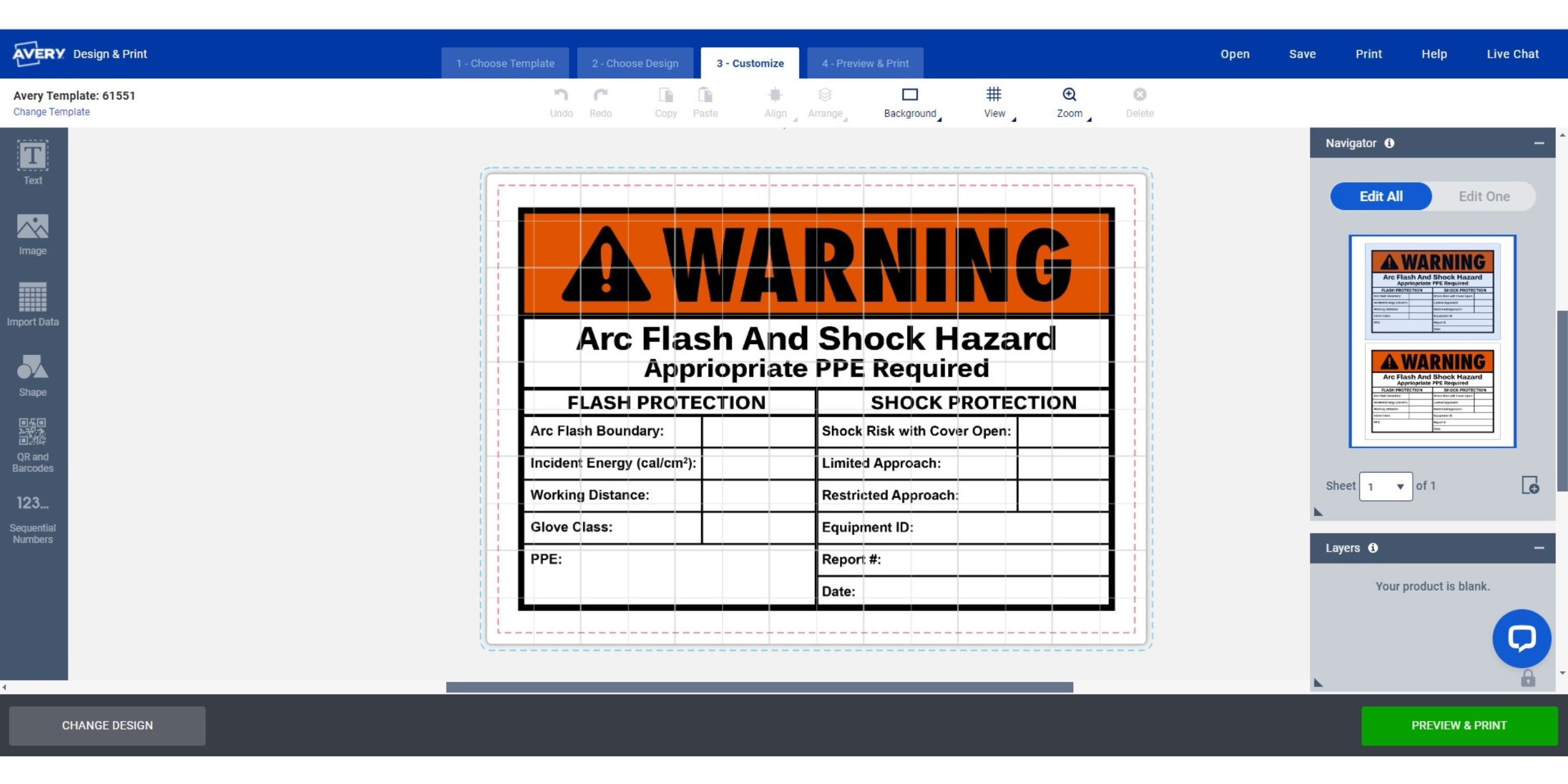

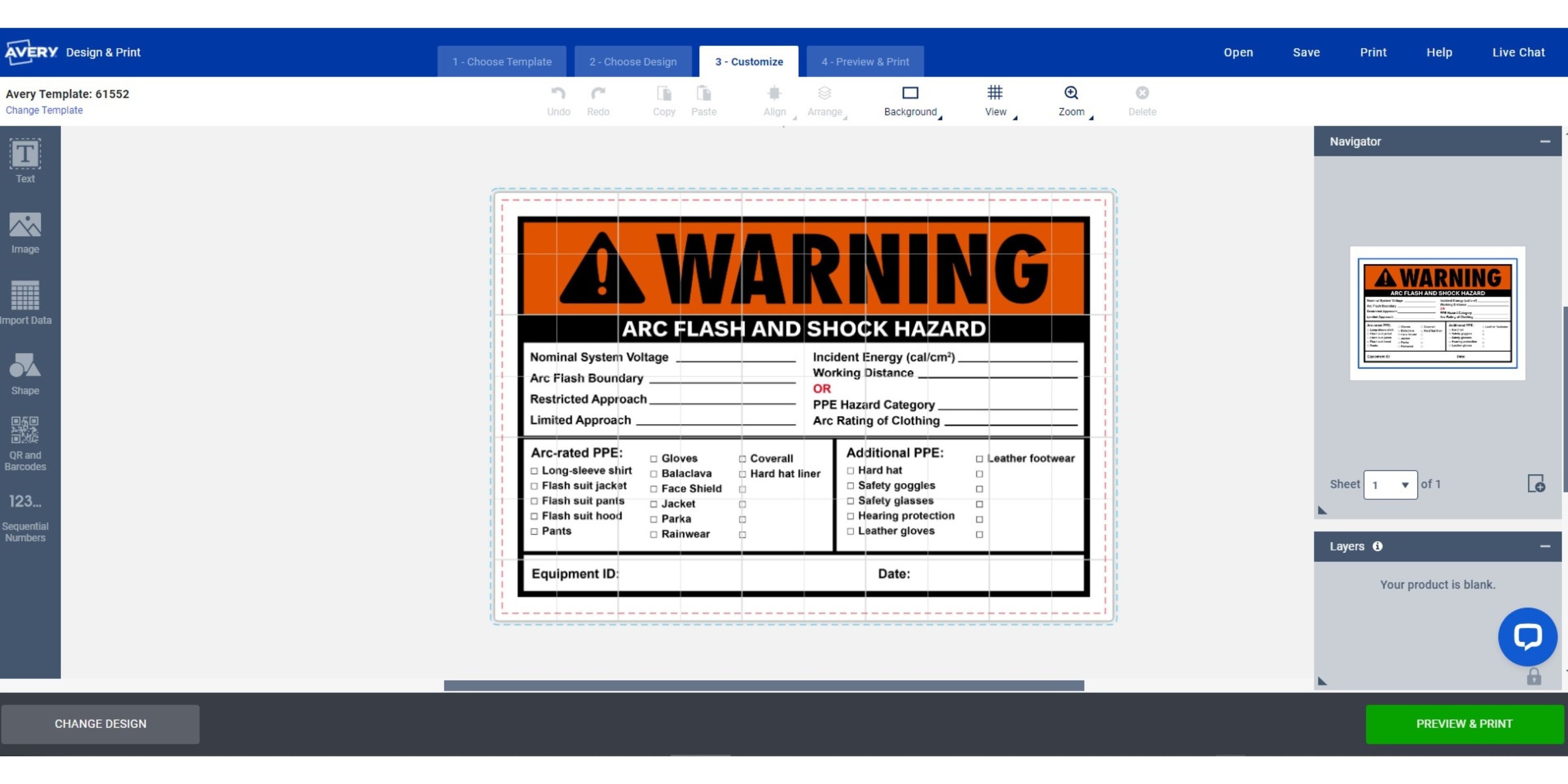

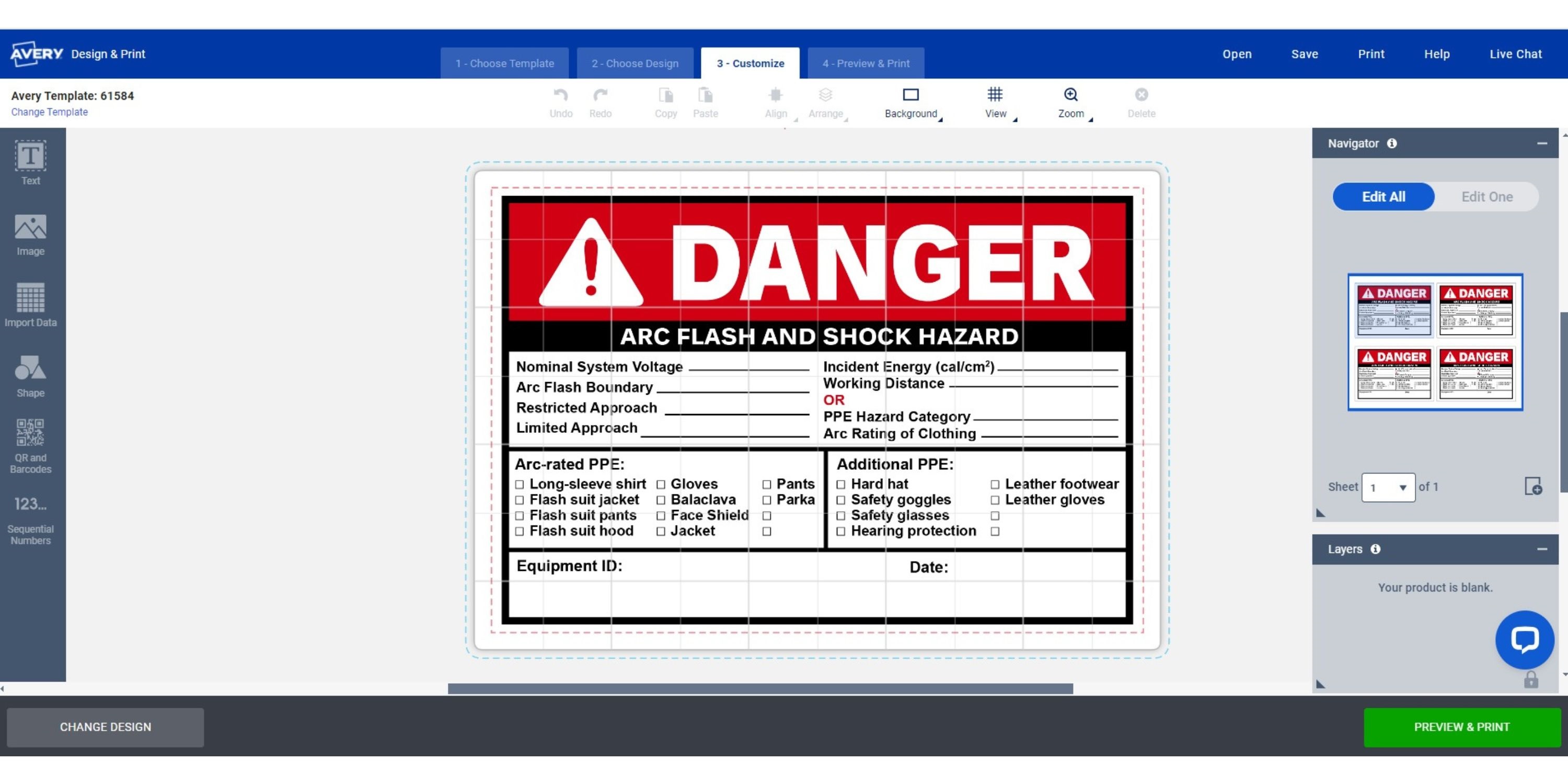

Most popular arc flash templates you can customize for free

Use the buttons next to each template below to order blank labels to print the template on and customize the template for free. You can also order the labels custom-printed by choosing “Let Us Print for You” after you’ve finished customizing the design. What’s more, once you save your project to your free Avery account, you can easily apply it to any other Avery product.

Arc flash templates for vinyl labels

UltraDuty GHS arc flash label templates

Helpful tips for printing on Avery labels

For the best print quality, go into your printer settings and set the scale to 100. Then, print a test sheet on plain paper to make sure everything is correct. If you don’t need to make any adjustments, go back to settings and change the printer type to “labels,” “cardstock,” “specialty,” or “heavy-weight.” These settings communicate to your printer that it will be printing on sheets that are thicker than regular paper.

Of course, you can also order custom-printed arc flash labels on a variety of label materials using our affordable custom-printing services. Order as few as two sheets of labels or hundreds of sheets, and your order ships in as little as three days.

Arc flash safety label FAQs

Does OSHA require arc flash labels?

In a nutshell, OSHA does require labeling for electrical safety, but it does not specify how to warn employees of specific hazards, for example, by requiring arc flash labels. To explain further, OSHA 29 CFR 1910 and 1926 cover requirements for electrical power generation, transmission, and distribution. While neither part specifies arc flash labels directly, two subparts discuss employer responsibilities for warning employees.

What are the relevant OSHA subparts

Firstly, 1910.303(e) states that “Electrical equipment must be marked with descriptive markings as necessary (voltage, current, wattage, etc.).” Secondly, 1910.335(b) states that “Employers must use alerting techniques (safety signs and tags, barricades, attendants, etc.) to warn and protect employees from hazards that could cause injury due to electric shock, burns, or failure of electric equipment parts.”

If you find these subparts confusing, you’re not alone. OSHA itself has discussed the interpretations of these regulations in more depth for that very reason.

Why do people use NFPA 70E guidelines?

Most people use NFPA 70E guidelines for arc flash safety because OSHA requirements are not always clear. Often, they describe what you must do (i.e., warn employees of electrical hazards), but not how to do it. The National Fire Protection Association (NFPA) standardizes safety guidelines and thoroughly covers a variety of arc flash label requirements. Most industry professionals accept these guidelines as a generally reliable way to communicate important safety information with electrical workers.

What are the 4 arc flash categories?

The four arc flash categories indicate levels of risk that help determine what type of PPE employees will need in order to work safely. Accordingly, each category requires a different level of protection.

- PPE Category 1: Minimum Arc Rating 4 cal/cm2

- PPE Category 2: Minimum Arc Rating 8 cal/cm2

- PPE Category 3: Minimum Arc Rating 25 cal/cm2

- PPE Category 4: Minimum Arc Rating 40 cal/cm2

Where should arc flash labels be placed?

Arc flash labels should be placed on electrical equipment where they can be seen when inspection, adjustment, and/or maintenance are required. Examples include switch boards, panel boards, industrial control panels, meter socket enclosures, and motor control centers.

More effective arc flash labels improve safety

Using clear, compliant labels that follow NFPA 70E guidelines is one way to significantly improve arc flash safety in your workplace. At the end of the day, the most important role of arc flash labels is to provide crucial information, communicate risks, and indicate the appropriate level of PPE to wear. What’s more, we’ve provided resources to help you start creating more effective labels today. For example, we’ve covered everything you need to know to create your own labels, including recommended sizes, materials, and how to find free, customizable Avery templates. For those who prefer a more hands-off approach, Avery WePrint® services are an affordable custom-printing alternative. Prioritize electrical safety and clear communication with arc flash labels that create a safer workplace for everyone.

Please note, the contents of this article and related articles on avery.com are for informational purposes only, are general in nature, and are not intended to and should not be relied upon or construed as a legal opinion or legal advice regarding any specific issue or factual circumstance.