Safety Signs Decoded: Who Makes the Rules (OSHA vs. ANSI)?

Why ANSI vs. OSHA matters for safety signs

When it comes to safety sign rules, OSHA vs. ANSI is a very common question. The most important thing to know is that OSHA and ANSI safety sign standards both aim to protect workers from hazards in the workplace. However, the two sets of standards come from different entities. While both sets of rules often work together, it can be tricky to figure out exactly what you need to know for safety sign compliance.

In this article, we’ll decode the rules of workplace safety signs and also share free templates to create your own compliant signs:

- Who are OSHA and ANSI?

- How do ANSI and OSHA work together?

- What are the different safety sign rules?

- Examples of OSHA and ANSI safety signs

Who are OSHA and ANSI?

OSHA: Occupational Safety and Health Administration

OSHA is a U.S. federal agency that sets and enforces standards for health and safety in American workplaces. It ensures compliance through targeted inspections and by investigating safety complaints, accidents, and fatalities.

Violations of OSHA standards can lead to significant penalties, ranging from hefty fines—potentially totaling from several thousand to hundreds of thousands of dollars—for failing to correct violations or for willful or repeated violations. In extreme cases, employers may face misdemeanor criminal charges for severe breaches of OSHA regulations, although this is relatively uncommon.

ANSI: American National Standards Institute

The American National Standards Institute (ANSI) is a non-profit group that’s been around for more than a century. They focus on creating agreed-upon standards to keep people safe, whether it’s consumers, workers, or the environment. Essentially, they bring together experts in different industries to decide on the best safety rules for everyone.

ANSI itself doesn’t make or enforce these standards. Instead, they provide accreditation (essentially, a thumbs up) to standards developed by other organizations. Their approval process makes sure that everyone’s voice is heard fairly and without bias, which helps build trust in the standards across different sectors, both private and public.

How ANSI and OSHA work together

ANSI gets the private and public sectors to agree on what safety sign standards they consider “best practices.” However, those standards are completely voluntary unless OSHA steps in and uses its legal power to enforce them. OSHA does this in three ways: (1) directly by adoption, (2) directly by reference, and (3) indirectly by citing ANSI standards in instances where failure to communicate a hazard resulted in injury, illness, or death.

1) OSHA adopting ANSI safety sign standards

ANSI-accredited best practices for safety signs have become the foundation for many safety sign standards enforced by OSHA today. In fact, OSHA based its first safety sign regulations on ANSI guidelines when it was founded in 1971. Even now, OSHA and ANSI maintain a close relationship, and OSHA may adopt ANSI guidelines at any time (thus making them mandatory).

2) OSHA safety sign rules that cite an ANSI standard

ANSI standards can become mandatory through something called “incorporation by reference.” This is the term for when a mandatory OSHA regulation cites a voluntary ANSI standard, making it mandatory by proxy. In these cases, failure to follow the ANSI standard may result in a citation from OSHA.

3) ANSI standards indirectly cited by OSHA

OSHA makes rules for safety signs, but they often don’t say exactly how employers should follow them. This can make things confusing when looking at the OSHA “General Duty Clause” (a part of the law called Section 5(a)(1) of the Occupational Safety and Health Act). This rule says that it is the employer’s duty to keep workplaces safe. So if there’s a complaint or someone gets hurt at work, OSHA investigates to determine if the employer knew about any dangers and if they told workers about them. They look at safety signs or other ways the company communicates hazards.

This is where ANSI standards come in because they are made with the agreement of experts. As such, it follows that if an ANSI standard exists, then the danger is known. Moreover, it shows that there was a way to warn about the danger, even if the employer didn’t use it.

Why doesn’t OSHA just make it simple and mandate total ANSI compliance?

OSHA has to find a middle ground between safety and what’s manageable for everyday businesses when creating safety sign rules. On the other hand, ANSI only focuses on safety when approving standards for safety signs. Even though OSHA can’t make every company follow ANSI safety sign rules, having ANSI around is still good for workers. This is because ANSI keeps updating safety sign guidelines, which OSHA can look to for advice. And companies can choose to use these standards whenever they want, helping keep workplaces safer.

What are the different safety sign rules?

OSHA safety sign types (required)

There are three types of safety signs that OSHA requires: 1) Danger, 2) Caution, and 3) Safety Instruction. They cover these signs under OSHA safety sign standard 1910.145, which also references ANSI standards Z53.1-1967 and Z535.1-2006 (R2011). As outlined above, this makes these specific ANSI signs mandatory because OSHA has incorporated them by reference.

Below are examples of the types of safety signs required by OSHA and recommended by ANSI. You can customize these safety sign templates for free using Avery Design and Print Online (ADPO). For printing the signs yourself, you have two options:

- Printable, blank 7″ x 10″ labels, which are available by the sheet in flexible quantities (just choose your material from the dropdown).

- 8-1/2″ x 11″ polyester sticker paper featuring removable Surface Safe® adhesive, which is available in convenient packs and can be removed without damaging walls.

You can also have your design custom-printed on a variety of materials using our affordable and convenient Avery WePrint® service.

OSHA safety sign examples

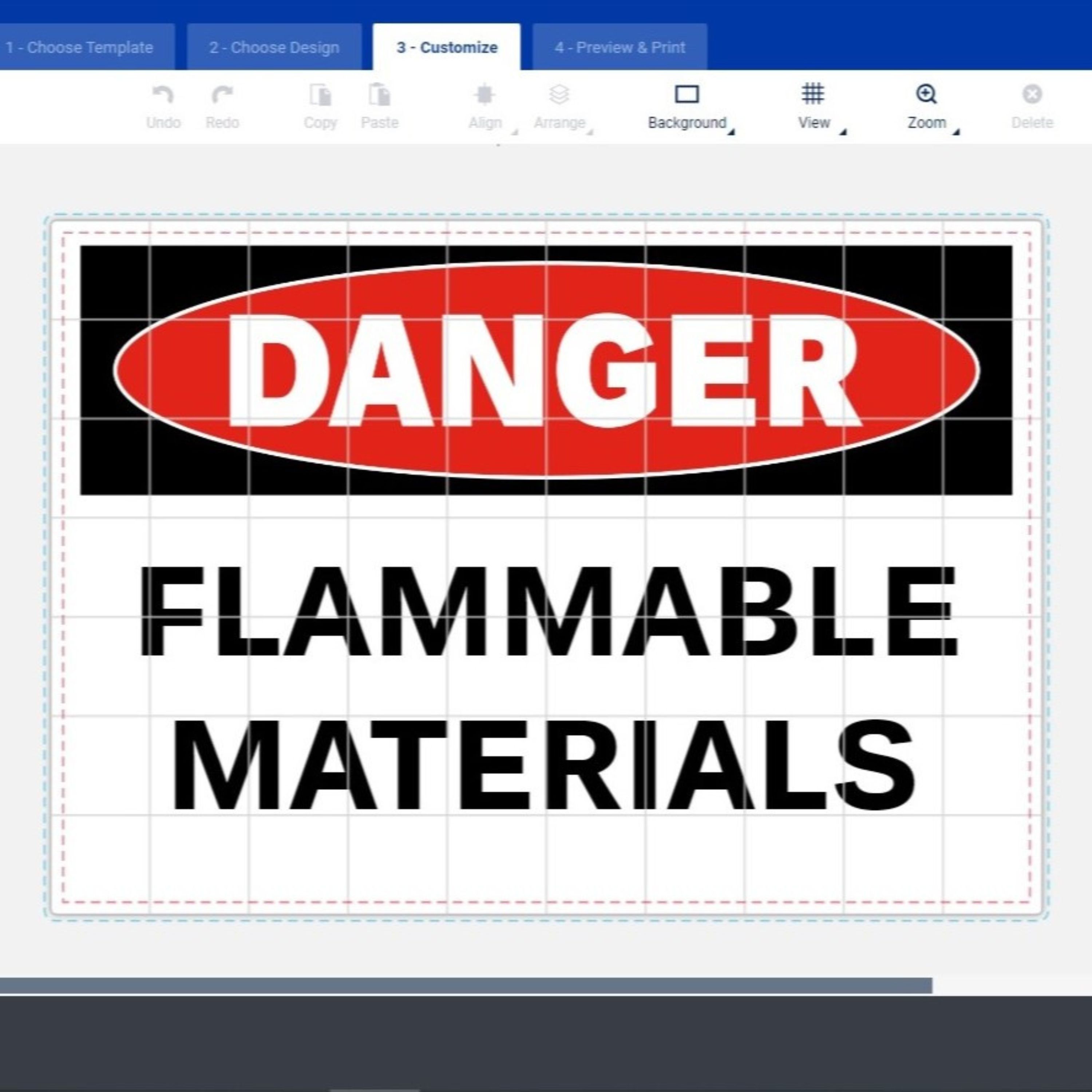

OSHA danger signs must be in red, black, and white. Use these signs to signal severe immediate danger and/or special precautions.

You can use this free template to create your own by editing the text and printing it out on a blank 7″ x 10″ label. Or, choose “Let Us Print for You” after customizing to order the design custom printed.

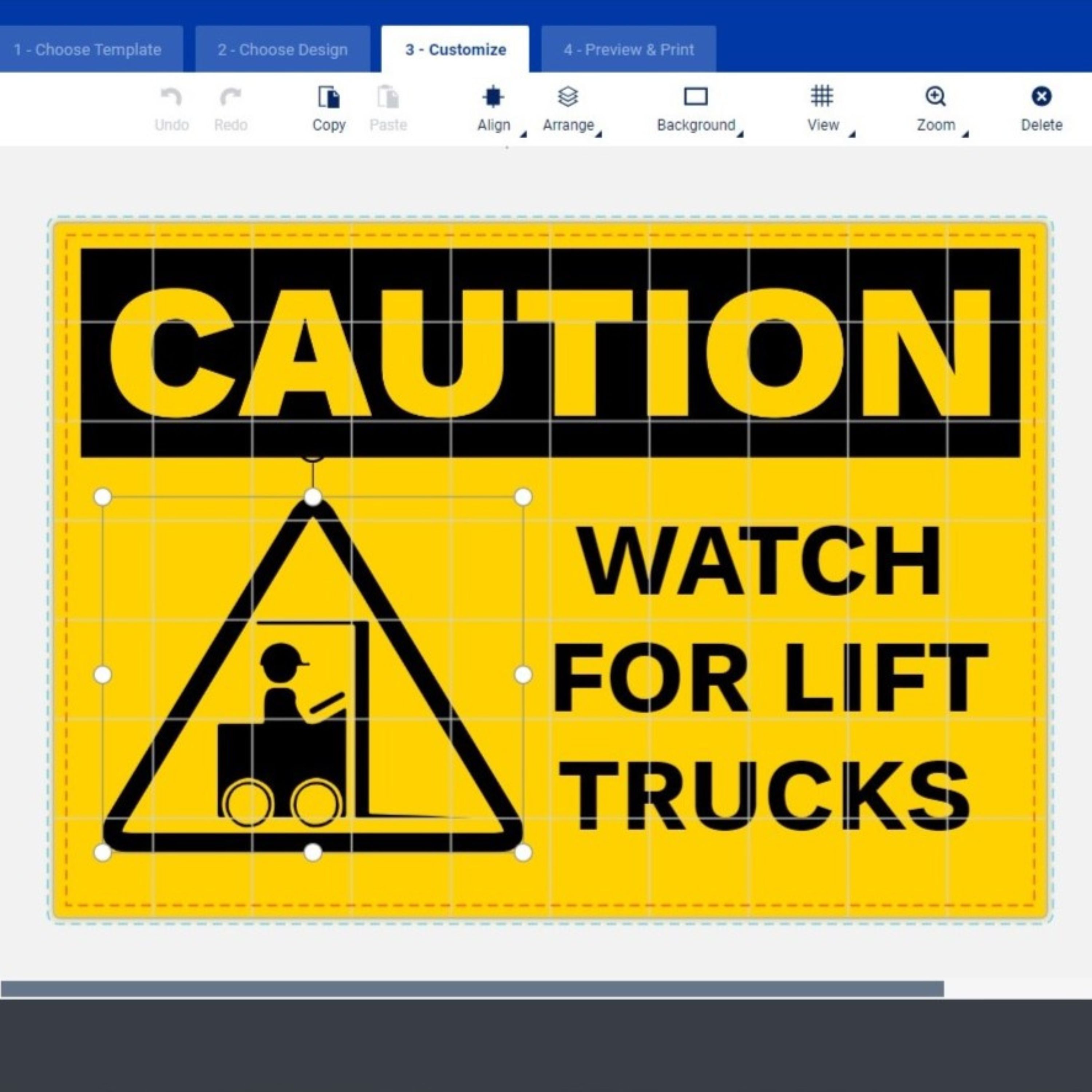

Use OSHA caution signs to warn against potential hazards and/or unsafe practices. They should be yellow with black letters, except for the header panel, which is black with yellow letters.

You can use this free template to create your own by editing the text and printing it out on a blank 7″ x 10″ label. Or, choose “Let Us Print for You” after customizing to order the design custom printed.

You should use safety instruction signs to provide information such as the type of PPE to use or instructions for safety equipment. The background must be white, and the panel should be green with white letters. Use only black letters on the white background.

You can use this free template to create your own by editing the text, then printing it out on a blank 8-1/2″ x 11″ label. Alternatively, you can finish customizing, then choose “Let Us Print for You” to order the design custom printed.

ANSI safety sign types (not required, but best practices)

ANSI recommends two additional types of safety signs: warning and notice signs. Although OSHA doesn’t demand it, many experts consider it best practice to use them. When you use warning and notice signs along with the ones that are required, it helps make workplace safety clearer for everyone.

ANSI safety sign examples

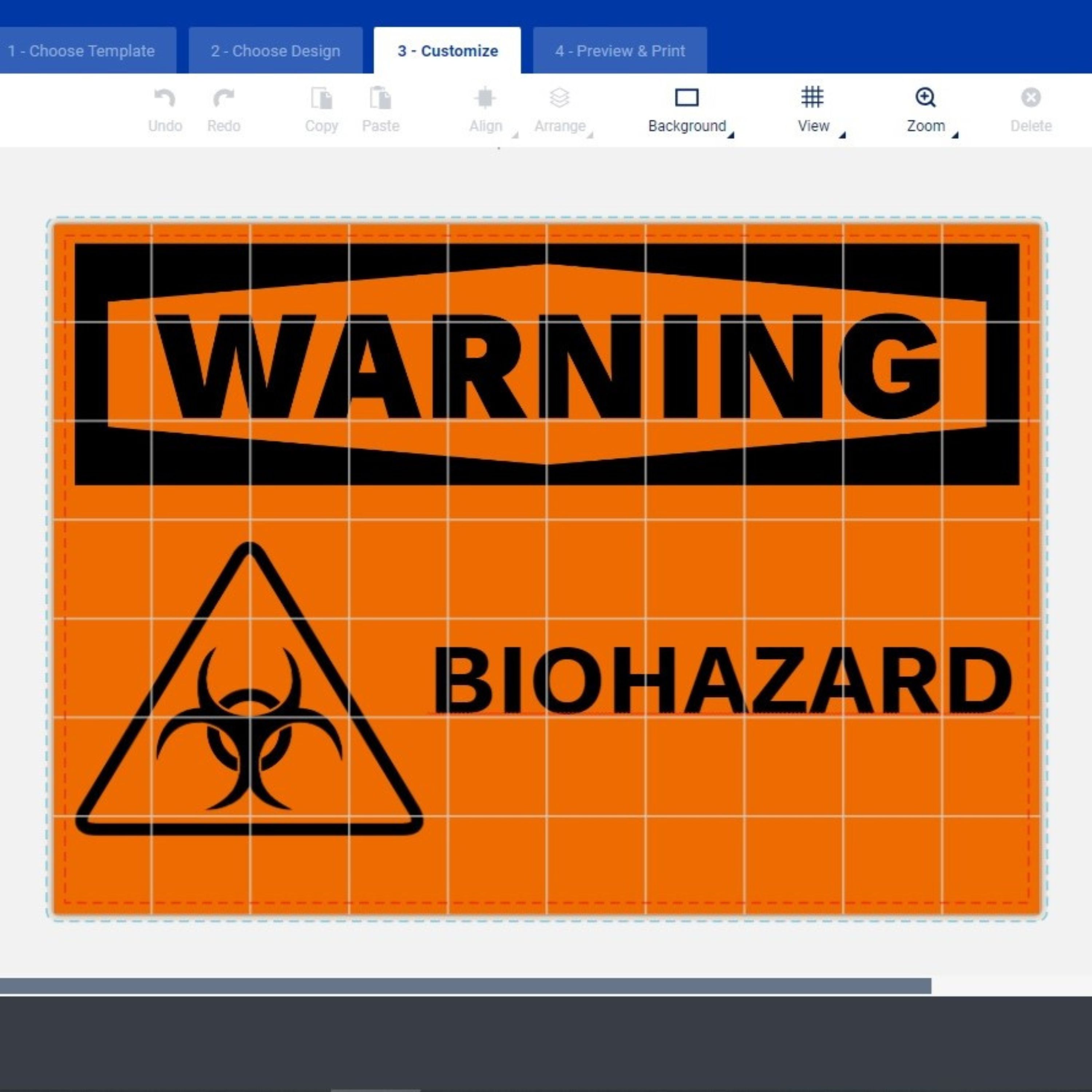

When you need to alert employees to a hazardous situation between “danger” and “caution,” you can use ANSI warning signs. Warning signs should have an orange background with black letters.

You can use this free template to create your own by editing the text and printing it out on a blank 7″ x 10″ label. Or, choose “Let Us Print for You” after customizing to order the design custom printed.

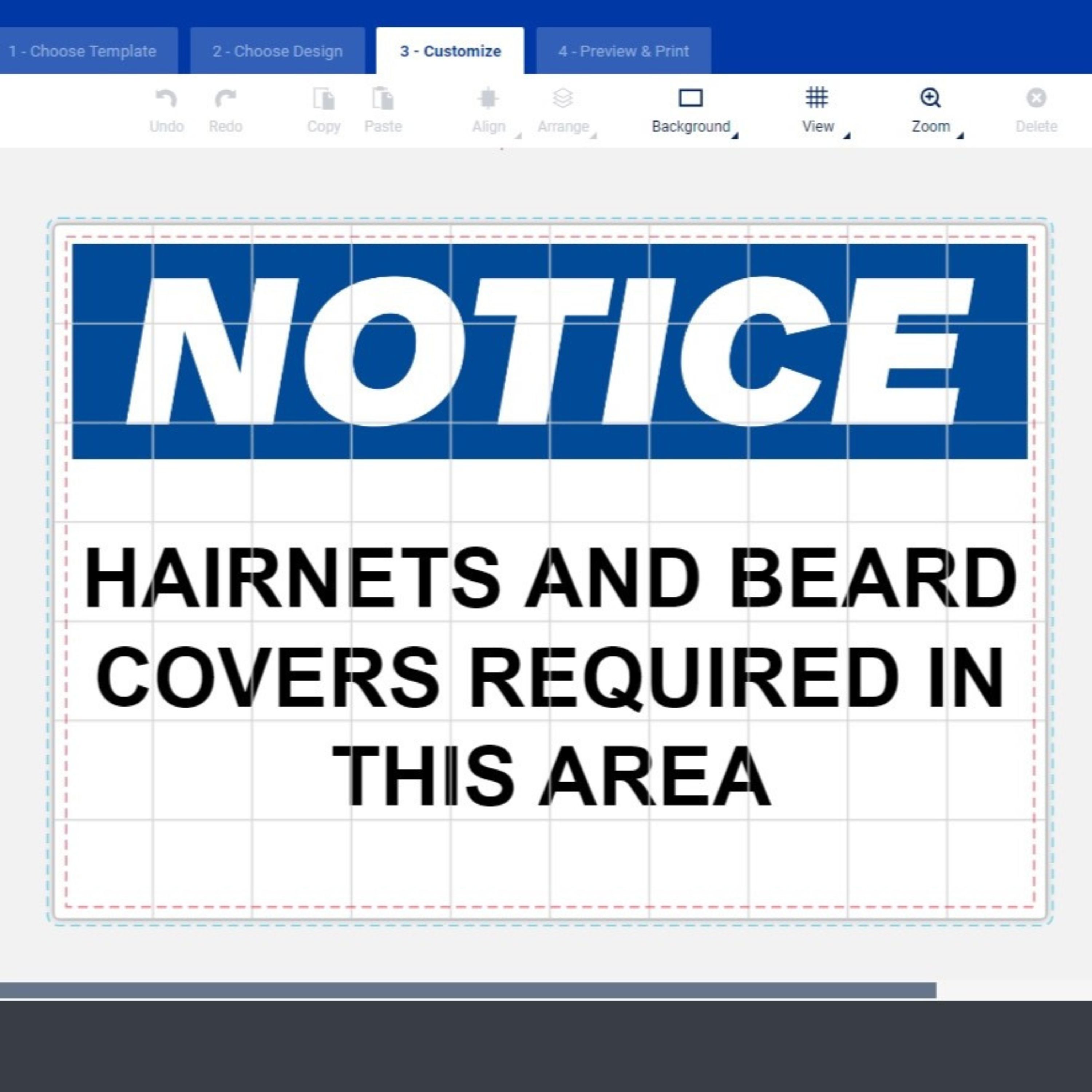

Use notice signs for information that is not directly related to personal injury but contributes to the overall safety and/or health of employees. OSHA notice signs have a white background, and the panel should be blue with white letters. Use only black letters on the white background.

You can use this free template to create your own by editing the text, then printing it out on a blank 8-1/2″ x 11″ label. Alternatively, you can finish customizing, then choose “Let Us Print for You” to order the design custom printed.

Understanding OSHA and ANSI safety signs

In conclusion, understanding the differences between OSHA and ANSI safety sign standards is crucial for maintaining a safe work environment. While both aim to protect workers, OSHA enforces mandatory regulations, while ANSI provides voluntary guidelines considered best practices.

By decoding OSHA’s role in setting mandatory standards and ANSI’s contribution to safety through voluntary guidelines, employers can navigate compliance effectively. Incorporating both types of safety signs—required by OSHA and recommended by ANSI—enhances workplace safety and clarity for employees.

Additionally, using the resources provided in this article, including free Avery templates for creating compliant safety signs, empowers businesses to prioritize safety. Remember, staying informed and implementing best practices not only ensures regulatory compliance but, more importantly, safeguards the well-being of workers.

Explore more workplace safety topics on our blog and join the conversation on Facebook.

Please note, the contents of this article and related articles on avery.com are for informational purposes only, are general in nature, and are not intended to and should not be relied upon or construed as a legal opinion or legal advice regarding any specific issue or factual circumstance.